PH stainless steel XM-13 丨PH13-8Mo

PH stainless steel XM-13 / PH13-8Mo / UNS S13800/ W.Nr 1.4534

Applications of stainless steel PH13-8Mo:

Stainless steel PH13-8Mo has been used for valve parts, fittings, cold-headed and machined fasteners, shafts, landing gear parts, pins, lockwashers, aircraft components, nuclear reactor components and petrochemical applications requiring resistance to stress-corrosion cracking.

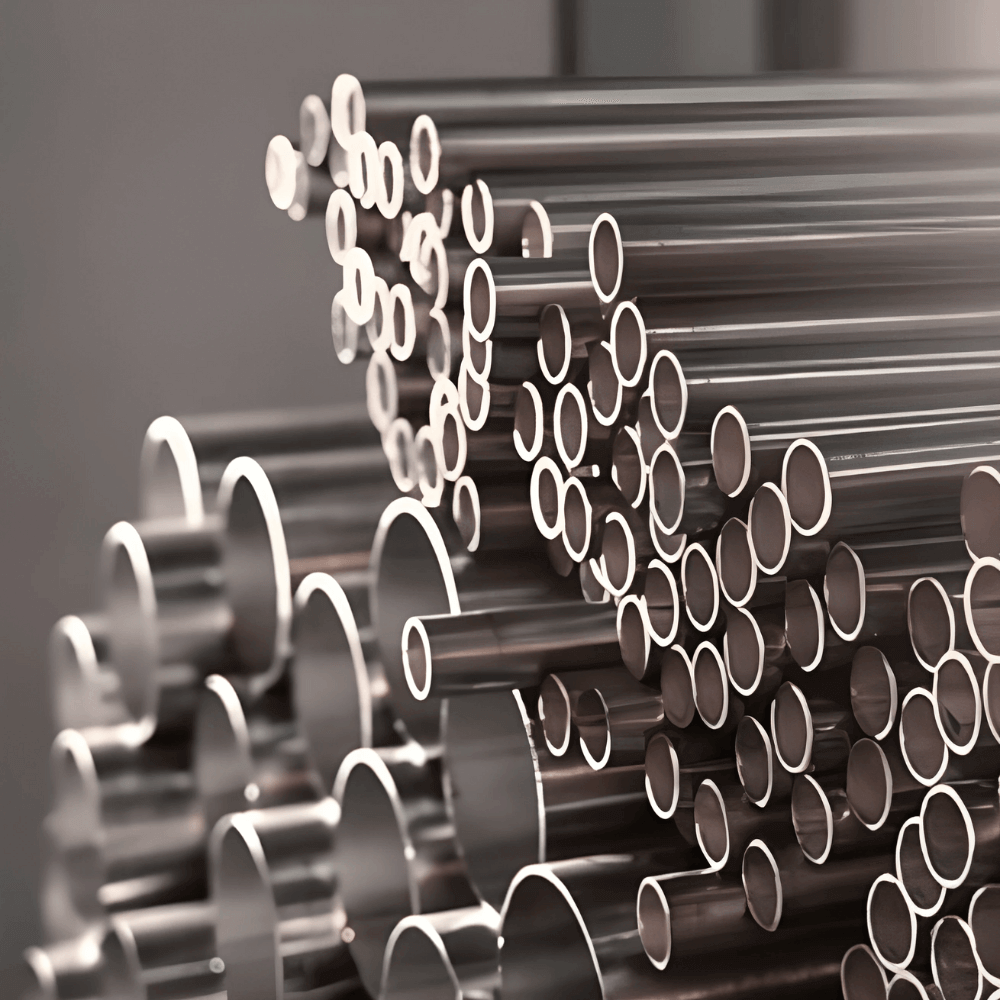

Normal product forms:

- Sheets, bars, coils, and wires.

- Round, square, hex (A/F), rectangle, billet, ingot, forged, etc.

- Forged hollow bar, forged ring, forging blocks, forging shaft, forging discs & circles.

Specifications/Standard: AMS 5864, AMS 5629, ASTM A 564, ASME SA564, ASTM A693, ASME SA693, ASTM A 705, ASME SA705.

- Chromium (Cr): 12.25-13.25%

- Nickel (Ni): 7.5-8.5%

- Molybdenum (Mo): 2.00-2.50%

- Aluminum (Al): 0.90-1.35%

- Carbon (C): 0.05% max

- Manganese (Mn): 0.1% max

- Silicon (Si): 0.1% max

- Nitrogen (N): 0.01% max

- Sulfur (S): 0.008% max

- Phosphorus (P): 0.01% max

Physical Constants and Thermal Properties

- Density: 4.48 g/cm³, Imperial: 0.28 lb/in³

- Melting Point: 1,404°C – 1,415°C, 2,560°F – 2,590°F

- Specific Heat Capacity: 0.50 J/g°C, 0.12 Btu/lb°F

- Thermal Conductivity: 13.8 W/m°C, 8 Btu-ft/hr/ft²/°F

Mechanical Property:

The mechanical properties of 13-8MoPH stainless steel vary depending on the heat treatment condition. For example, in the H950 condition, it has an ultimate tensile strength of 220 ksi, a 0.2% yield strength of 205 ksi, an elongation of 10% in 2D, a reduction of area of 45%, and a Rockwell C hardness of 45.