PH stainless steel 15-5PH 丨 XM-12

Stainless steel 15-5PH, a martensitic precipitation-hardening alloy with around 15% Chromium and 5% Nickel, boasts exceptional strength, hardness, and corrosion resistance. Its strength can be augmented through a single low-temperature heat treatment. Compared to 17-4 PH, it exhibits superior transverse toughness, ductility, mechanical properties in larger cross-sections, and forgeability. It’s easily weldable and machinable in various Thermal Conditions.

PH stainless steel 15-5PH / XM-12 / UNS S15500/ W.Nr 1.4545

Applications of stainless steel 15-5PH:

PH stainless steel XM-12/15-5PH is widely used in the chemical, petrochemical, offshore, paper, and aerospace industries. It is used to create gears, shafts, fittings, valves, cylinders, engine parts, and fasteners.

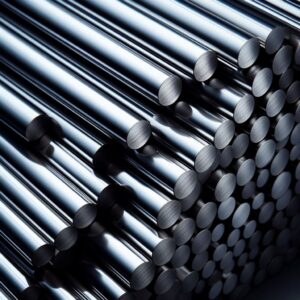

Normal product forms:

- Sheets, bars, coils, and wires.

- Round, square, hex (A/F), rectangle, billet, ingot, forged, etc.

- Forged hollow bar, forged ring, forging blocks, forging shaft, forging discs & circles.

Specifications/Standard: ASTM A564, AMS 5659 TYPE 1, AMS 5659 TYPE 2, ASTM-A-484, ASME SA564

Chemical Composition:

- Chromium (Cr): 14.0-15.5%

- Nickel (Ni): 3.5-5.5%

- Copper (Cu): 2.5-4.5%

- Iron (Fe): Balance

- Carbon (C): 0.05% max

- Manganese (Mn): 1.0% max

- Silicon (Si): 1.0% max

Physical Constants and Thermal Properties

- Latent Heat of Fusion: 280 J/g

- Maximum Temperature: Corrosion 440 °C (830 °F)

- Maximum Temperature: Mechanical 820 °C (1510 °F)

- Melting Completion (Liquidus): 1430 °C (2600 °F)

Mechanical Property:

- Brinell Hardness: 290 to 430

- Elastic (Young’s, Tensile) Modulus: 190 GPa (28 x 10^6 psi)