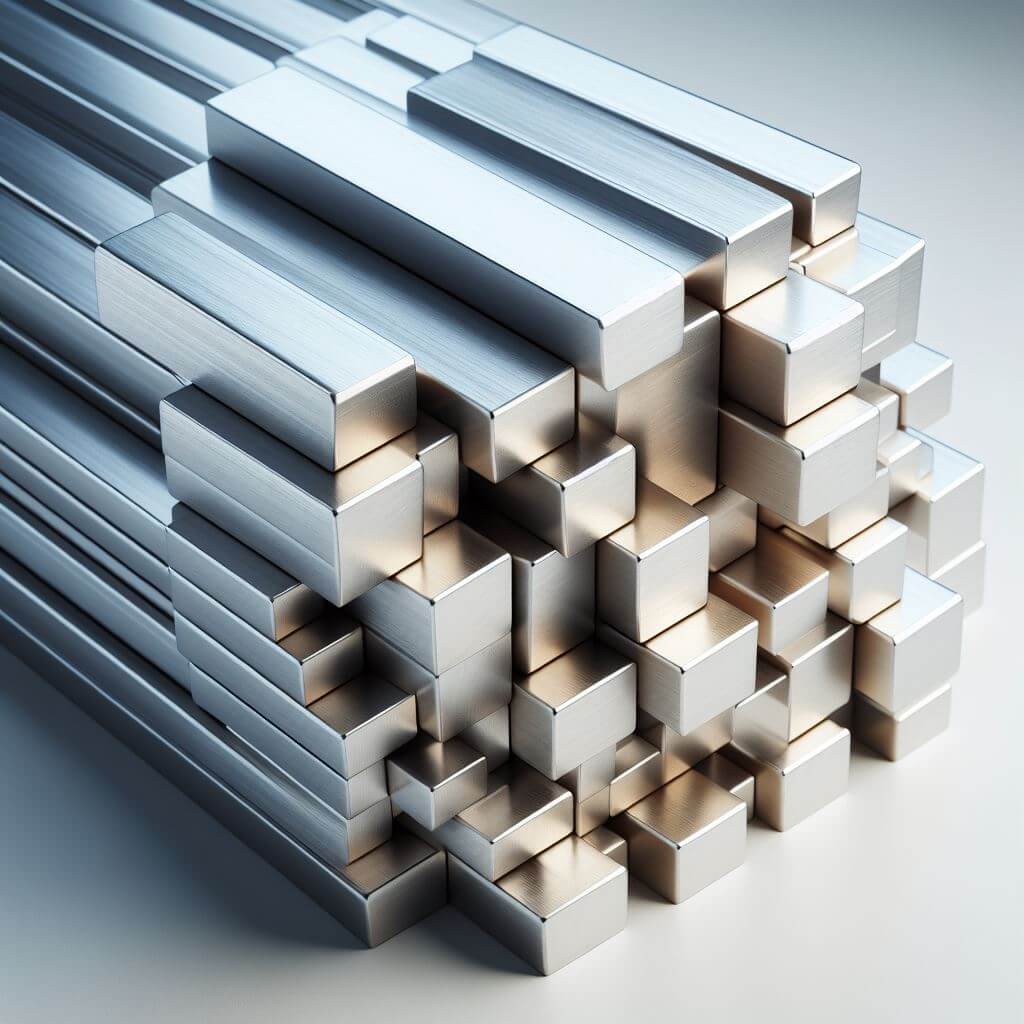

Inconel 690丨UNS N06690

Nickel alloy Inconel 690, also known as UNS N06690, is a high-chromium nickel alloy with excellent resistance to many corrosive aqueous media and high-temperature atmospheres. The alloy’s high chromium content gives it excellent resistance to aqueous corrosion by oxidizing acids (especially nitric acid) and salts, and to sulfidation at high temperatures. In addition to its corrosion resistance, alloy 690 has high strength, good metallurgical stability, and favorable fabrication characteristics.