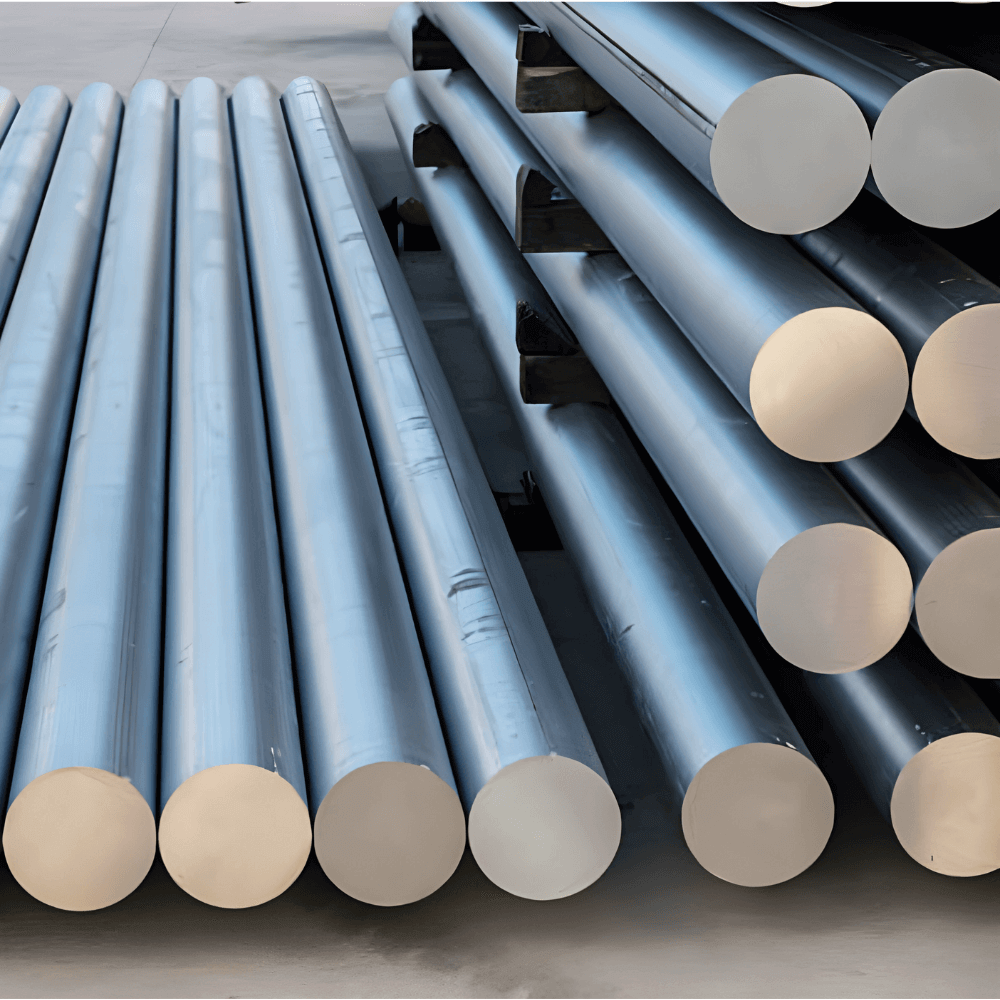

Inconel 600丨UNS N06600

Inconel 600, known as UNS N06600, is a nickel-chromium alloy with good oxidation resistance at high temperatures and resistance to chloride-ion stress-corrosion cracking, corrosion by high-purity water, and caustic corrosion. Service temperatures for alloy 600 can be from cryogenic to 2000°F (1093℃). This alloy has good workability, weldability, and high strength.