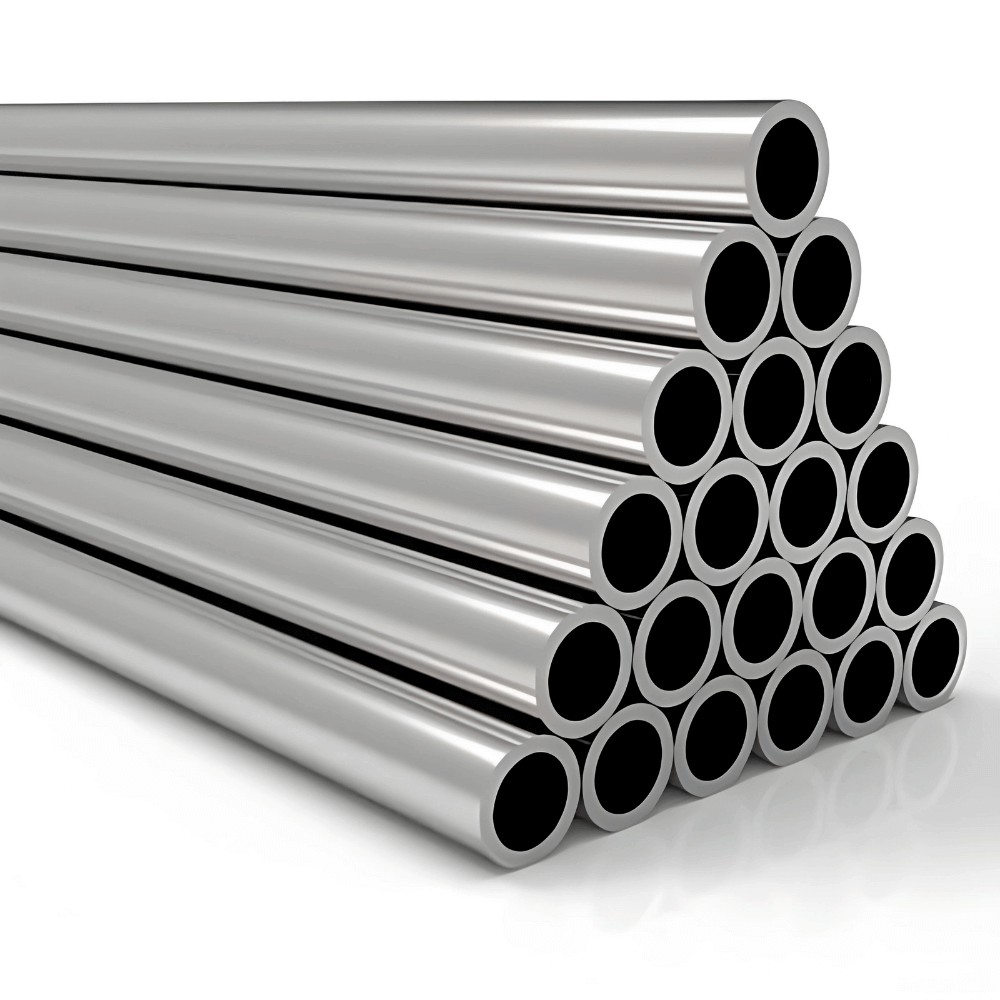

Incoloy 825丨UNS N08825

Incoloy 825, known as UNS N08825, is a nickel-iron-chromium alloy with additions of molybdenum and copper. It has excellent resistance to both reducing and oxidizing acids, stress-corrosion cracking, and localized attacks such as pitting and crevice corrosion. The alloy is especially resistant to sulfuric and phosphoric acids.