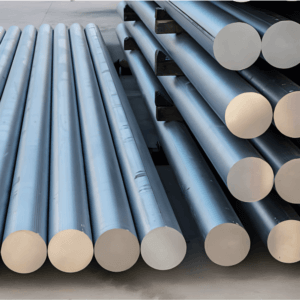

Incoloy 800H & 800HT丨N08810 & N08811

Nickel alloys 800H & 800HT, are nickel-iron-chromium alloys that have the same basic composition as INCOLOY alloy 800 but with significantly higher creep-rupture strength. The higher strength results from close control of the carbon, aluminum, and titanium contents in conjunction with a high-temperature anneal.