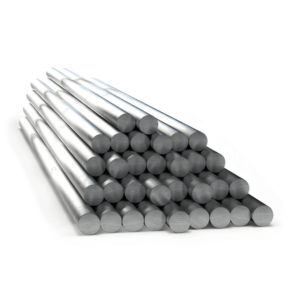

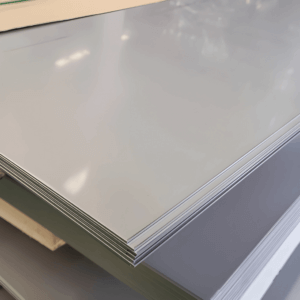

Hastelloy B2丨UNS N10665

Hastelloy Alloy B2, also known as UNS N10665, is a solid solution-strengthened nickel-molybdenum alloy. It exhibits excellent corrosion resistance in various reducing media, able to withstand corrosion by hydrochloric acid at any temperature and concentration under atmospheric pressure. It also demonstrates outstanding corrosion resistance in moderately concentrated non-oxidizing sulfuric acid, various concentrations of phosphoric acid, high-temperature acetic acid, and organic acids such as formic acid, bromic acid, and hydrogen chloride gas. Additionally, it is resistant to corrosion by halogen catalysts.