Duplex Stainless Steel 2507

Super duplex stainless steel 2507 epitomizes the convergence of formidable strength with unparalleled corrosion resistance. Thriving in high chloride and elevated temperature settings, this material exhibits remarkable resistance to both general corrosion and localized forms, such as pitting and crevice corrosion. Its duplex microstructure further fortifies its resilience against stress corrosion cracking. Like its counterparts in the duplex realm, super duplex stainless steel 2507 is ill-suited for extremes of temperature, with advisories against operating below -50°C or exceeding +300°C due to potential compromises in toughness.

Duplex stainless steel 2507 / UNS S32750 / W.Nr. 1.4410

Applications of stainless steel 2507:

- Oil and Gas Industry: Pipelines, subsea equipment, risers, heat exchangers, and other components that are exposed to corrosive environments.

- Chemical Processing: Pressure vessels, reactors, tanks, and piping systems.

- Desalination Plants: Heat exchangers, pumps, and piping systems.

- Marine and Offshore Structures: Shipbuilding, offshore platforms, and structures.

- Pulp and Paper Industry: Digesters, bleach towers, and pulp-handling systems.

- Power Generation: Heat exchangers, boilers, condensers, and flue gas cleaning systems.

- Construction and Architecture: Building facades, bridges, infrastructure projects, and other structural elements.

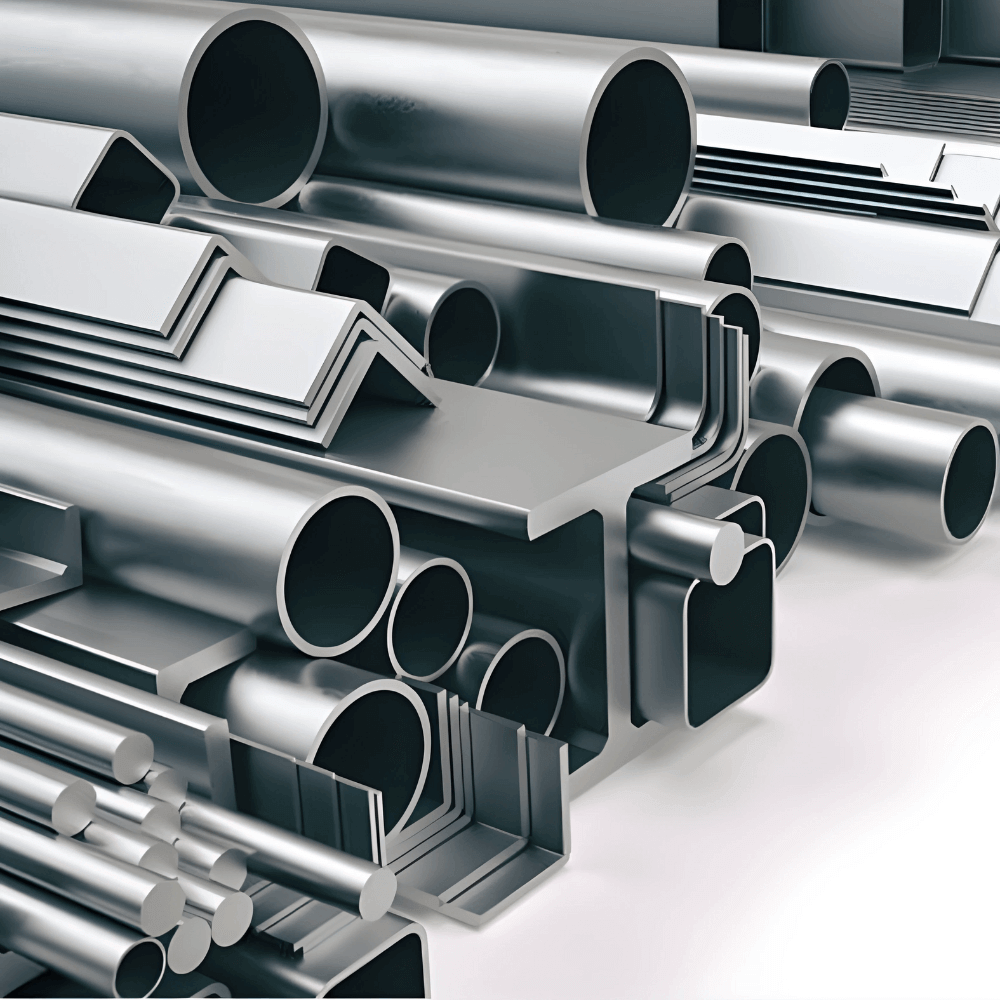

Normal product forms:

- Round, Square, Hexagon, Flat Bars & Wires

- Seamless / Welded Pipes & Tubes

- Hot & Cold Rolled Plates & Sheets

- Forged Bars

- Forged Flanges

- Pipe Fittings

- Fasteners

Specifications/Standard: ASTM A240, EN 10088-2, ASTM A276, A479, A484, EN 10088-3, ASTM A182, ASTM A790

Chemical Composition:

- Chromium (Cr): 24-26%

- Nickel (Ni): 6-8%

- Molybdenum (Mo): 3-5%

- Manganese (Mn): 1.20% max

- Silicon (Si): 0.80% max

- Copper (Cu): 0.50% max

- Nitrogen (N): 0.35% max

- Phosphorous (P): 0.035% max

- Carbon (C): 0.030% max

- Sulfur (S): 0.020% max

- Iron (Fe): Balance

Physical Constants and Thermal Properties

- Density: 7.8 g/cm³

- Melting point: 1410-1460°C

- Poisson’s Ratio: 0.3

- Electrical Resistivity: 0.80 ohm m x 10⁻⁶

- High thermal conductivity

- Low coefficient of thermal expansion

Mechanical Property:

- 0.2% Offset Yield Strength: ≥280 N/mm²

- Tensile Strength: 580-800 N/mm²

- Elongation: ≥40/30%

- Modulus of Elasticity: 200 kN/mm²

- The mechanical properties of 2507 are 50-100% higher than most austenitic stainless steels due to its dual phase structure and high nitrogen content.