Austenitic Stainless Steel 654SMO

654SMO is a highly alloyed super austenitic stainless steel comprised of 23% nickel, 25% chromium, and 7% molybdenum. With its austenitic structure, it proves suitable for diverse temperature ranges. Offering corrosion resistance on par with top nickel-based alloys, it boasts excellent local corrosion resistance, pitting resistance, and stress corrosion resistance in challenging environments like seawater, aeration, gaps, and low-speed scouring conditions. It serves as an excellent alternative to both nickel-based and titanium alloys.

Austenitic stainless steel 654SMO / UNS S32654 / W.Nr. 1.4652

Applications of stainless steel 654SMO:

- Refining, chemical equipment.

- Flue gas desulfurization device for thermal power generation, wastewater treatment.

- Atomic power generation, comprehensive utilization of coal, and ocean wave power generation.

- Marine structures in the sea environment, seawater desalination, marine aquaculture, seawater heat exchange.

- Salt production, soy sauce brewing food field.

- Paper industry, high concentration chloride ion environment of various bleaching devices.

- Oil and gas industry equipment.

- Offshore platforms, heat exchangers, underwater equipment, firefighting equipment.

- Chemical processing industry, utensils, and pipeline industry.

- Desalted plants, high-pressure RO plants, and submarine pipelines.

- High-strength, corrosion-resistant mechanical equipment and components.

Normal product forms:

- Round, Square, Hexagon, Flat Bars & Wires

- Seamless / Welded Pipes & Tubes

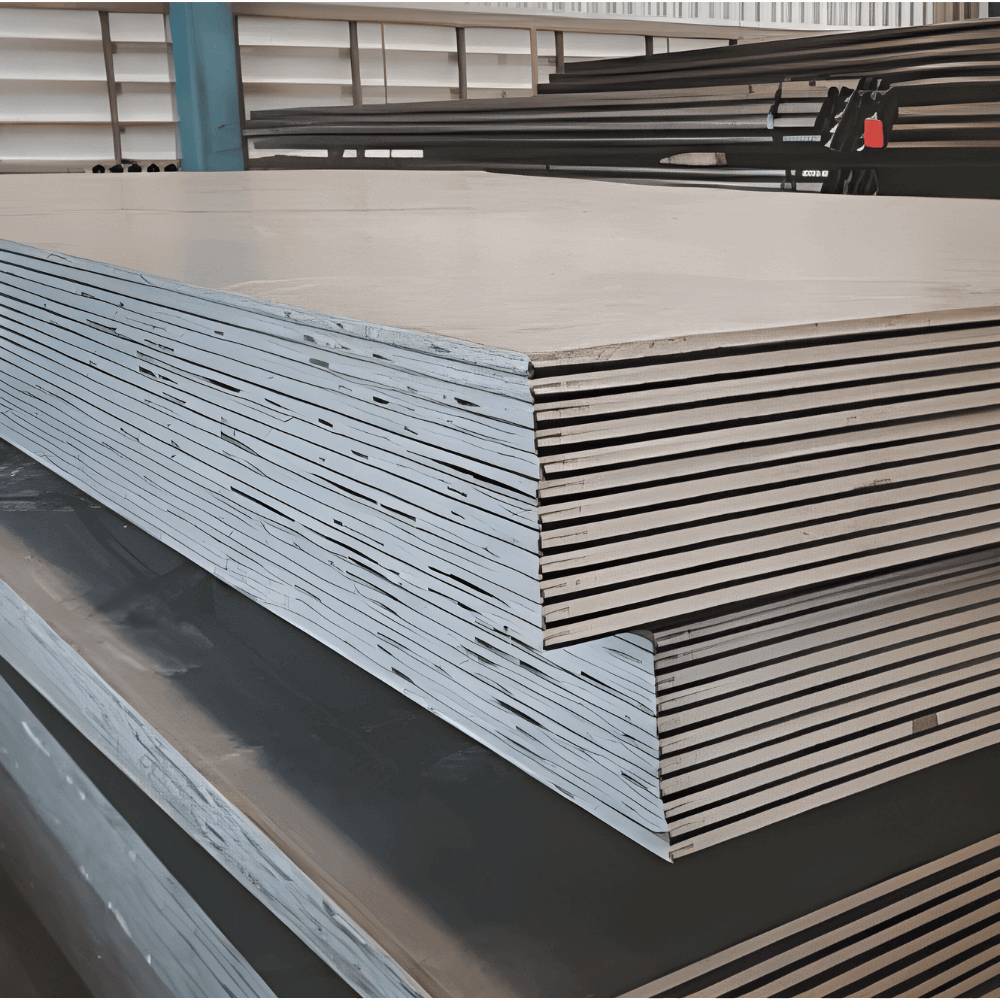

- Hot & Cold Rolled Plates & Sheets

- Forged Bars

- Forged Flanges

- Butt-Weld Pipe Fittings

- Socket-Weld/Forged Pipe Fittings

- Machined Components

Specifications/Standard: ASTM UNS S32654, EN 1.4652

Chemical Composition:

- Chromium (Cr): 24-25% max

- Nickel (Ni): 21-23% max

- Molybdenum (Mo): 7.0-8.0%

- Copper (Cu): 0.3-0.6%

- Carbon (C): 0.02% max

- Silicon (Si): 0.50% max

- Manganese (Mn): 4.00% max

- Phosphorus (P): 0.03% max

- Sulfur (S): 0.005% max

- Nitrogen (N): 0.55% max

Physical Constants and Thermal Properties

- Density: 7.88 g/cm³

- Melting Range: 2525-2630 ℉

- Thermal Conductivity (W/m-K): 19.0

Mechanical Property:

- Tensile Strength: 621 MPa

- Elastic Modulus: 200 GPa