Austenitic Stainless Steel 254SMO

254SMO is a very high-end austenitic stainless steel. It is designed with a combination of impact toughness resistance to chloride stress corrosion cracking, and pitting and crevice corrosion. The strength of 254SMO is twice that of the stainless steel 300 series. 254SMO has been reported to be a cost-effective substitute for high nickel and titanium alloys.

Austenitic stainless steel 254SMO / UNS S31254 / W.Nr. 1.4547

Applications of stainless steel 254SMO:

- Marine structures in the sea environment, seawater desalination, marine aquaculture, seawater heat exchange.

- Flue gas desulfurization device for thermal power generation, wastewater treatment.

- Atomic power generation, comprehensive utilization of coal, and ocean wave power generation.

- Refining, chemical equipment.

- Salt making, soy sauce brewing.

- Paper industry, various bleaching devices.

Normal product forms:

- Round, Square, Hexagon, Flat Bars & Wires

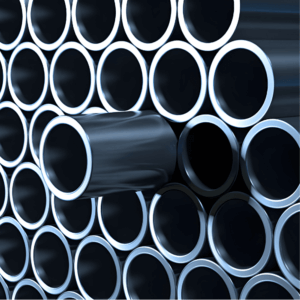

- Seamless / Welded Pipes & Tubes

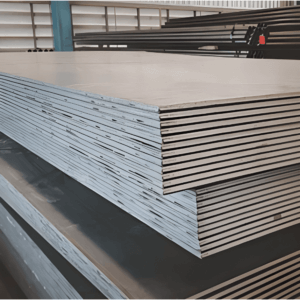

- Hot & Cold Rolled Plates & Sheets

- Forged Bars

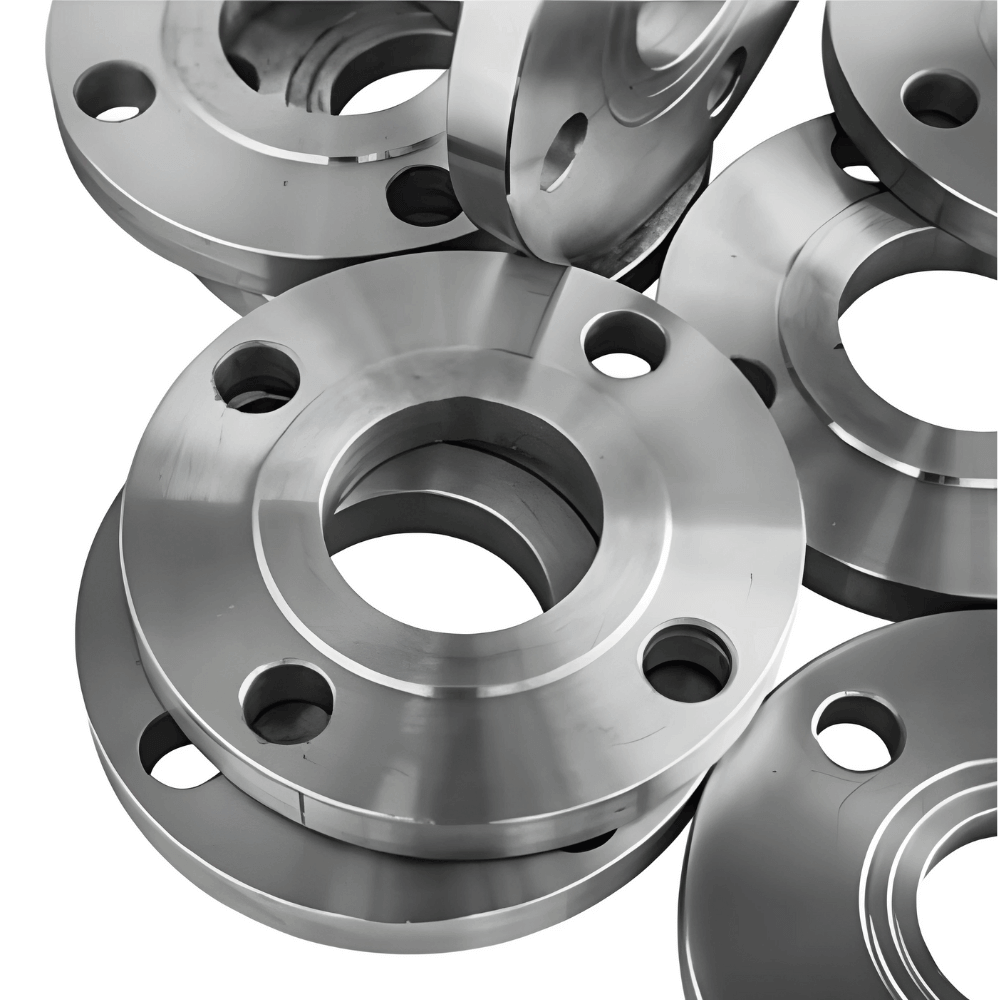

- Forged Flanges

- Butt-Weld Pipe Fittings

- Socket-Weld/Forged Pipe Fittings

- Machined Components

- Ferrule Compression Fittings

- Welding Consumables

Specifications/Standard: ASTM A813, ASTM A469, ASTM A269, ASTM A240, ASTM A182 (F44), ASTM A814, ASTM A312, ASTM A249.

Chemical Composition:

- Iron (Fe): 55.69%

- Chromium (Cr): 20%

- Nickel (Ni): 18%

- Molybdenum (Mo): 6.1%

- Nitrogen (N): 0.20% max

- Carbon (C): 0.020% max

Physical Constants and Thermal Properties

- Density: 8 g/cm³

- Thermal expansion co-efficient (@20-100°C/68-212°F): 16.5 µm/m°C

- Thermal conductivity: 14 W/mK

Mechanical Property:

- Tensile strength: 680 MPa

- Yield strength: 300 MPa

- Modulus of elasticity: 195 GPa

- Shear modulus: 75 GPa

- Poisson’s ratio: 0.30

- Elongation at break: 50%

- Hardness, Brinell: 210