Abstract: Inconel 625 alloy can be welded using the gas tungsten arc welding (GTAW) method with argon shielding, reducing labor intensity. A suitable inverter welding machine that meets both argon arc and manual arc welding can be chosen. For GTAW, direct current electrode positive (DCEN) is preferred, while for shielded metal arc welding (SMAW), direct current electrode negative (DCEP) is recommended. The inverter welding machine should have excellent IGBT inverter technology, stable power supply characteristics (steep drop or constant current), various argon arc operation modes, high-frequency arc ignition, strong welding penetration, and energy-saving features.

Welding Material Selection: Considering various factors, including chemical composition, mechanical properties, and environmental conditions, the following welding materials are recommended for Inconel 625 alloy:

- Welding Wire (GTAW): ERNICRMO-3

- The chemical composition of ERNICRMO-3 wire closely matches that of the base material.

- It contains elements like Ni, Cr, Co, and Mo, which complement the alloying elements in the weld pool and reduce dilution effects.

- ERNICRMO-3 wire has good mechanical properties, including tensile strength greater than 760 MPa.

- Welding Rod (SMAW): ENICRMO-3

- ENICRMO-3 welding rod has similar composition to the base material.

- It provides good crack resistance due to its low hydrogen content.

- The Cr content in ENICRMO-3 contributes to corrosion resistance in the weld metal.

- Quality Considerations:

- Imported welding materials (such as ENICRMO-3) may offer better quality and uniformity, reducing rework during welding and overall construction costs.

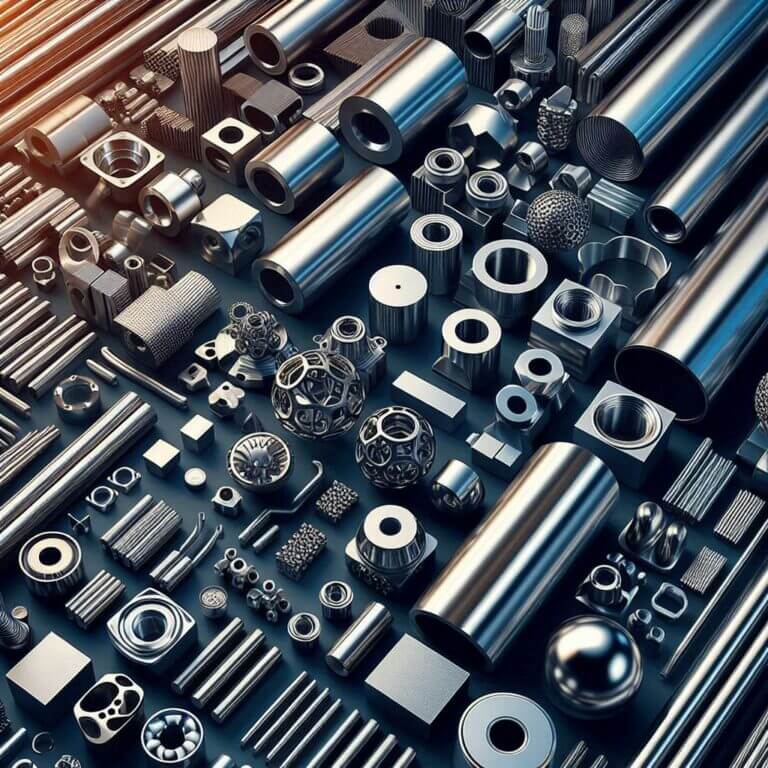

At J&A Alloy, we stock normal forms of nickel-based alloys, corrosion-resistant alloys, and super stainless steel, such as sheet, rod, pipe, etc., customized products are also available. Please feel free to connect with us to explore advanced alloy materials.

Hangzhou J&A Alloy Co.,Ltd

Website: www.jaalloy.com

Email: info@jaalloy.com